This webpage is a reprint, with minor stylistic alterations to suit the internet, of a paper with the same title, presented to the MATES 99 (Metering and Tariffs for Energy Supply) Conference held at Birmingham (England), 25-28 May 1999. IEE Conference Publication No CP462.

Copyright © Institution of Electrical Engineers, United Kingdom, 1998 and 1999. Reproduced here by permission.

Early

diagnosis of tariff metering faults by a systematic analysis of Main/Check

metering discrepancies.

R G Chambers.

Chambers Metercare (Consultant) Chambers Metercare Home Page

SUMMARY

A method is

described by which the integrity of MWh tariff metering systems in a Power

Station can be monitored remotely by a systematic analysis of the discrepancies

between the Main and Check meter readings. The method is cheap to implement,

using only metering data that is already in existence; it is also highly

effective in detecting tariff metering faults at an early stage of development.

The technique is recommended for metering systems on large generators, where

the financial losses resulting from inaccurate metering can be substantial.

INTRODUCTION

The electrical

energy registered by the tariff metering on a base-load 500MW generator

normally yields an annual income of around US $170M. A metering error of

-0.1% might therefore entail a loss of US $170,000 per year to the

generating company. For this reason, there is a strong financial incentive to

maintain the accuracy of generator metering to a high standard at all times.

The method described here is an analysis tool that will help the power station

to identify cost-effectively any metering system whose accuracy is drifting, so

that repairs can be effected at an earlier stage.

The Station (or

the Generating Company) keeps a database of the Main and Check MWh meter

readings for each Generator, for every half-hour metering period; this is the

duplicate of the metering database that is accessed daily by Settlements to

arrange for tariff payment. In the analysis method to be described here, the

discrepancies between the Main and Check MWh data are analysed by a database

macro, linked manually to a separate spreadsheet macro. The resulting graphs

and analysed summaries give a clear indication when a metering system has

started to drift out of calibration. The method is both cheap and effective in

detecting the onset of calibration drift, for the following reasons:

1. The primary

metering database is produced automatically by the metering system, at no extra

cost;

2. The method

of analysis is intrinsically simple;

3. The graphs

output by the analysis technique (usually) invite unmistakable conclusions on

the health of the metering system;

4. The results

of the analysis often allow a prima facie diagnosis of the cause of the

observed drift in calibration;

5. The analysis

can be done remotely, using a modem and telephone link to get the data from the

meter to the office where the analysis is performed.

DEFINITION OF

MAIN/CHECK METERING DISCREPANCY.

The Main/Check

discrepancy of a sister pair of meters, in any half-hour metering period, is

defined by:-

discrepancy = 100 ( M - C )/M percent

where M and C are

the values of MWh registered by the Main and Check meters respectively during

the metering period under study.

PRINCIPLE OF

THE DISCREPANCY ANALYSIS TECHNIQUE

A metering system

basically consists of the CTs, the VTs, wiring (including fuses, switches and electrical

joints) to connect these to the meter, and the meter itself. If the instrument

transformers remain stable, if the wiring remains in good condition, and if the

calibration characteristic of the meter itself remains constant, then there

should never be any drift in the overall calibration of the metering system

over all time. If both the Main and the Check MWh metering systems remain in

this perfect condition, the plot of the Main/Check metering discrepancy against

time, measured in years, should be a horizontal straight line running parallel

to the time axis of the graph. Any drift in the overall calibration of any

component of either the Main or the Check metering system will cause the graph

to become a sloping line. The degree of slope indicates the rapidity with which

calibration accuracy of one of these metering systems is drifting.

The method is at its most useful where both the Main meter and the Check meter is fed by its own individual set of VTs and CTs. In an inferior metering system where the Main and Check MWh meters share a common VT (or CT), a drift in the calibration accuracy of the VT would affect both metering systems equally, not producing any change in the Main/Check discrepancy.

LONG-TERM DRIFT OF THE MAIN/CHECK METERING DISCREPANCY.

The errors of a

MWh metering system vary naturally, sometimes by as much as 0.2%, according to

the value of MW and MVAr load being measured. If these natural variations were

allowed to exist in the data, they would confuse any attempt to produce a

meaningful long-term graph of the variation of Main/Check meter deviation with

time. For this reason, each metering data point is accepted as valid for

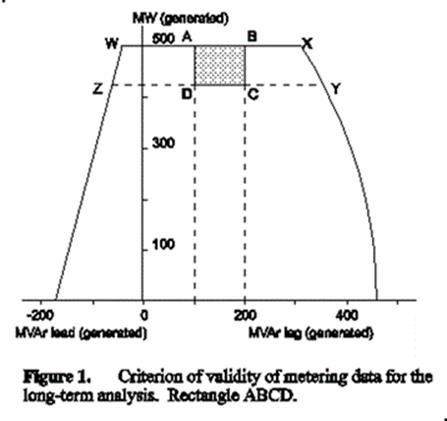

analysis only if it falls within the box ABCD of the machine capability

diagram, Figure 1. Any metering data that falls outside this box is not used in

the analysis. This policy ensures consistency of the data in graphs that may

cover periods of several years.

![[Graph: Long-term]](paper_files/image004.gif)

Figure 2 shows the

plot of MWh Main/Check metering discrepancy against time, over a four-year

period, for Generator A and its associated Unit Transformer. Each plotted point

on the graph is the average of all the metering data collected over a one-week

interval that satisfies the validity criterion described above. Each plotted

point in Figure 2 is therefore the average of between 10 and 200 readings, the

actual number depending on the load regime of the generator for that week. Over

a one-year period between April 1994 and April 1995, the Main/Check discrepancy

of the Generator MWh meters gradually changed from -0.1% to +0.3%. At this

time, it was not normal practice to save the metering data of the Unit

Transformer for long. To the extent that data is available in Figure 2, the

Main/Check discrepancy of the Unit Transformer was changing in a manner that

mimicked the behaviour of the Generator metering. In August 1995, the Check MWh

metering of both the Generator and the Unit Transformer failed altogether. Investigation

by the Station revealed that the HV fuse protecting the 22kV side of one phase

of the Check VT had become open-circuit. They replaced the fuse (see Arrow A of

Figure 2); the Main/Check discrepancy of both items of plant returned to

approximately the same value as had existed in April 1994, before the

fuse-failure had started to develop.

At the time of

this fault, the Station had the routine of looking at their Main/Check

discrepancies once a week or once a fortnight. Nobody ever drew a graph showing

the long-term variation of the Main/Check discrepancy. The fault grew slowly,

over a fifteen-month period from May 1994 to August 1995 (Figure 2). The

changes developed so slowly that nobody noticed them. The final complete

failure of the Check metering was a surprise to the Station staff. If they had

had access to graphs shown in Figure 2, they would have been aware of the

developing fault as early as December 1994, and the failure would have been

rectified before it caused any appreciable trouble.

The failure of an

HV fuse protecting a VT is often a slow process taking months or years. Wright

and Newbery (1) describe the corona-discharge erosion process which attacks the

fuse element and is responsible for the failure. This type of failure is possible

at VT voltages of 12kV (line) or above, but becomes an increasingly likely mode

of failure for higher voltages. Because failures can take place so slowly, a

week-by-week visual inspection of the Main/Check discrepancy figures is never

likely to detect the growing fault. A graphical technique is the only method by

which a slowly-developing fault can be reliably detected at an early stage of

development.

MEDIUM-TERM DRIFT OF THE MAIN/CHECK METERING DISCREPANCY.

![[Graph: Medium-term, with mimicking]](paper_files/image006.gif)

In some investigations of metering accuracy, a medium-term or short-term plot of Main/Check discrepancy may be required. The spreadsheet macros we have developed are able to do this. A medium-term plot for Generator B and its associated Unit Transformer is shown in Figure 3. The plot covers a period of six months; data for the graph was selected by the criteria of Figure 1. Each plotted point is the nine-point moving average of the measured point itself, the four preceding, and the four succeeding points. The graph of Figure 3 was drawn because the routinely-produced long-term graph showed the start of an excursion, and the Station wished to discover more details about what might be the cause. The excursion of Main/Check discrepancy of the Generator metering in late February was -0.25%, and was mimicked by the behaviour of the Unit Transformer metering. Once again, a fault in the VT signal is indicated, since this is the only input signal shared by both sets of metering. The cause of the problem was quickly diagnosed: a knife-switch on the VT secondary signal had a high-resistance electrical contact.

NON-MIMICKED CHANGES OF THE MAIN/CHECK

DISCREPANCY.

![[Graph: Non-mimicked discrepancy]](paper_files/image008.gif)

This Section

assumes that the metering system under study includes separate Unit Transformer

and Generator metering. The Unit Transformer Main MWh meter shares a VT signal

with the Generator Main MWh meter; and similarly for the Check metering.

When a fault

develops in an individual Generator meter, the changes of Main/Check

discrepancy would not normally be mimicked by the Unit Transformer metering.

The same is (theoretically) true for any fault that might develop in the CT

signal, although the present author has not yet observed a CT fault using the

techniques described here. The presence of mimicking is therefore diagnostic of

a fault in the VT signal, while the absence of mimicking indicates either a

meter fault or a fault in the CT signal.

Figure 4 shows the

abrupt change of Main/Check discrepancy that occurred when an

out-of-calibration Generator MWh meter was replaced by a newly calibrated one.

As described in the previous paragraph, the change of meter characteristic

affected only the Generator metering, while the Main/Check discrepancy of the

Unit Transformer metering continued at its previous value.

USE OF THE

TECHNIQUE FOR ASSESSING MAINTENANCE WORK ON THE METERING.

Figure 4

illustrates another valuable feature of the spreadsheet macros. The ability to

easily plot out Main/Check metering discrepancies can be a useful tool for

assessing the calibration of a metering system after maintenance work has been

done on any of its components. The metering engineer responsible for the

maintenance can easily assess whether the jump in the graph in Figure 4

corresponds with the expected outcome of the work.

DETECTION OF A PHASE-ANGLE ERROR IN THE

METER OR IN A METERING SIGNAL.

![[Graph vs tan(phi); no fault.]](paper_files/image010.gif)

If the phase-angle

compensation of a Generator MWh meter is perfectly set up to cancel the

(actually existing) values of phase-angle errors of both the CT and the VT, the

meter should theoretically give accurate measurements at all values of power

factor angle phi. Furthermore, if both the Main and the Check meter are

perfectly set up in this way, the plot of Main/Check discrepancy against tan (phi)

should yield a line of best fit which runs parallel to the tan (phi)

axis, as in the observed results of Figure 5. The graphical data in Figure 5 is

from Generator B for the interval from January to early February 1998. This was

the period (see Figure 3) when the Main/Check discrepancies were stable, and

when the metering was fault-free.

The validity

criterion for data in the graph of Figure 5 is different from what has been

used up to now. To be valid for the present analysis, the load must fall in the

box WXYZ of Figure 1. This extension beyond the original MW/MVAr validity

box ABCD is necessary if we are to obtain a wide range of power factor angle

phi for the graph.

![[Graph vs tan(phi); with fault.]](paper_files/image012.gif)

Now consider the

situation when the phase-angle compensation of the MWh meter becomes mismatched

with the actually existing CT or VT phase errors. The resulting meter error is

theoretically proportional to tan (phi). Figure 6 shows the result of a linear

regression analysis for Generator B in the interval from late February to early

March 1998; this was a period when the metering was known, from Figure 3, to

have problems. At the 95% statistical confidence level, the slope of the line

of best fit in Figure 6 is 0.16 ± 0.06 percent/unit of tan (phi). A

theoretical analysis has shown that a slope of this magnitude would be obtained

if one (electrical) phase of the VT signal had a phase (angle) error of 0.49

centiradians. This amount of phase-angle error is unacceptable for the class of

metering used on Generator B.

We have therefore

seen that the method of analysis can detect metering faults by a graphical

technique of plotting Main/Check discrepancy against tan (phi). Graphs

of this type can easily be obtained from the metering database by use of the

spreadsheet macro.

ANALYSIS OF THE

STATISTICAL SPREAD (STANDARD DEVIATION) OF THE METERING DISCREPANCIES.

The vertical

scatter of the data points in Figure 6 has a full range (maximum - minimum) of

0.42%. This compares with a full-range scatter in Figure 5 of 0.09%.

The value of 0.09%

occurred when the metering was in a healthy state, while the value 0.42%

occurred when there were problems caused by a high-resistance contact in the

knife-switch. Any loose or dirty electrical contact, whether in an electrical

connection or (hypothetically) in a dry solder joint on a meter circuit board,

has a contact resistance which varies unpredictably. At any given time, the

resistance might be zero, or it might be sufficiently high to affect the signal

at or in the meter. This explains why some types of fault

may be accompanied by (and diagnosed by) an increased statistical variation of

the metering discrepancy values. Our software automatically calculates the

standard deviation of the discrepancy values for each meter, and reports any

meter which has an unusually high spread.

COMPANY-WIDE /HISTOGRAM

OF METERING DISCREPANCY VALUES.

![[Main/Check histogram]](paper_files/image014.gif)

Figure 7 is a

histogram of the MWh discrepancy values of the generators of two companies combined, as found in April 1998. The histogram

is produced annually, and is a useful tool for planning the meter maintenance

programme for the year ahead. Special maintenance attention is normally planned

for those metering systems that lie at the extreme left or the extreme right of

the histogram.

CONCLUSIONS

The database and

spreadsheet macros are effective in identifying metering faults at an early

stage of development. The technique is cheap to implement and simple to

understand.

REFERENCE

Wright, A. and

Newbery, P.G., 1982.

"Electric Fuses", First Edition, Peter

Peregrinus Ltd, London.

Contact

Information

The author has now retired, but will be happy

to answer any queries that arise from this paper.

Dick Chambers

Chambers Metercare

58 Primley Park Avenue

Leeds

LS17 7HU

England.

e-mail

[email protected]

Telephone

+44 (0)113-268-4406

Chambers Metercare

Home Page http://www.metercare.co.uk/index.htm